LIONFIX Dyes

LIONZOL ‘Vinyl Sulphone’ Based

These are vinyl sulphone based reactive dyes widely used for dyeing & printing of cellulosic fibres for its very good fastnes.

| LIONZOL "VS" | C.I. Number | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Substantivity | Solubility at 30°C | Dischargability | Day Light 1/1 & 1/6 | Washing ISO4 | Hypochlorite Bleach | Exhaust 40 C & 60°C | One Bath Pad Batch | One Bath Pad Dry Steam | ||||||||

| 1% | 4% | |||||||||||||||

| Yellow-FG | Y 42 | L | 100 | G | 4-5 | 5 | 5 | 5 | 1 | FS | S | S | S | S | ||

| Yellow-GL | Y 37 | H | 80 | G | 6 | 4 | 5 | 5 | 2-3 | S | S | S | S | FS | ||

| G. Yellow-G | Y 17 | H | 100 | G | 4-5, 6 | 5 | 5 | 5 | 1 | S | S | S | S | FS | ||

| Yellow-GR | Y 15 | H | 100 | G | 4-5, 6 | 5 | 5 | 5 | 1 | S | S | S | S | FS | ||

| G. Yellow-RNL | Y 107 | M | 100 | G | 4-5, 5 | 4-5 | 5 | 5 | 1 | S | S | S | S | S | ||

| G.Yellow-R | Y 77 | H | 150 | G | 4-5, 4 | 4-5 | 4 | 4 | 1-2 | S | S | FS | FS | S | ||

| Orange-3R | O 16 | H | 80 | G | 5-6 | 4-5 | 4-5 | 4-5 | 1 | S | NS | S | S | S | ||

| Red-5B | R 35 | L | 80 | G | 3-4 | 5 | 5 | 5 | 1 | FS | S | S | S | S | ||

| Red-BB | R 21 | M | 100 | P | 5 | 5 | 4-5 | 4-5 | 4 | S | S | S | S | S | ||

| Red-RB | R 198 | M | 100 | F | 5 | 4-5 | 4 | 4-5 | 4 | S | S | S | S | S | ||

| Red-BS | R 111 | H | 80 | G | 5-6 | 4-5 | 4-5 | 4-5 | 1 | S | NS | S | S | S | ||

| Red-CD | R 278 | L | 80 | G | 3-4, 4 | 5 | 5 | 5 | 1 | FS | S | S | S | S | ||

| Violet-5R | V 5 | M | 100 | P | 5-6 | 4 | 5 | 5 | 2 | S | S | S | S | FS | ||

| T. Blue-G | B 21 | H | 80 | P | 6 | 4-5 | 4-5 | 4-5 | 3 | S | S | S | S | S | ||

| Blue-3R | B 28 | H | 80 | G | 6 | 4-5 | 4-5 | 4-5 | 3 | S | S | S | S | S | ||

| Blue-BB | B 220 | M | 100 | G | 4-5 | 5 | 4 | 4-5 | 2-3 | FS | S | FS | FS | S | ||

| Blue-R | B 19 | L | 150 | F | 4-5 | 5 | 5 | 4-5 | 4 | FS | S | FS | FS | S | ||

| N. Blue-GG | B 203 | M | 100 | F | 4-5 | 4-5 | 4-7 | 4-5 | 2-3 | S | S | FS | FS | S | ||

| Green-6B | B 38 | M | 80 | G | 5-6 | 5 | 5 | 5 | 1 | S | S | S | S | S | ||

| Black-RL | BL 31 | H | 100 | F | 6 | 5 | 5 | 5 | 1 | S | S | S | S | S | ||

| Black-B | BL 5 | H | 150 | G | 4 | 5 | 5 | 5 | 1 | S | S | S | S | S | ||

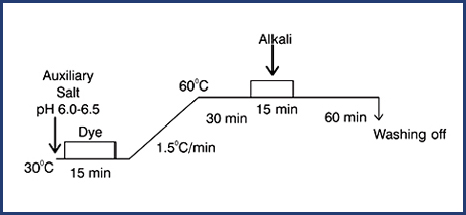

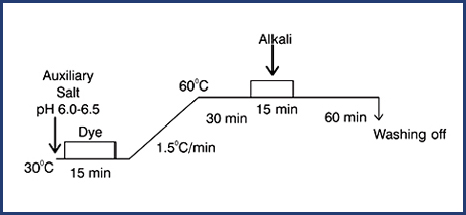

| Single Alkali Method | ||

|---|---|---|

| % Dye | Common Salt(g/l) | Soda Ash(g/l) |

| <0.1 | 20 | 5 |

| 0.1 – 0.5 | 20 – 25 | 5 – 7 |

| 0.5 – 1.0 | 25 – 40 | 7 – 10 |

| 1.0 – 2.0 | 40 – 50 | 10 – 13 |

| 2.0 – 3.0 | 50 – 60 | 13 – 15 |

| 3.0 – 5.0 | 60 – 80 | 15 – 20 |

| 5.0 – 7.0 | 80 – 90 | 20 |

| >7.0 | 100 | 20 |

| Mixed Alkali Method | |||

|---|---|---|---|

| % Dye | Common Salt(g/l) | Soda Ash(g/l) | Caustic Flakes(g/l) |

| <0.1 | 20 | 5 | 0 |

| 0.1 – 0.5 | 20 – 25 | 5 | 0.3 – 0.38 |

| 0.5 – 1.0 | 25 – 40 | 5 | 0.38 – 0.45 |

| 1.0 – 2.0 | 40 – 50 | 5 | 0.45 – 0.6 |

| 2.0 – 3.0 | 50 – 60 | 5 | 0.6 – 0.75 |

| 3.0 – 5.0 | 60 – 80 | 5 | 0.75 – 1.0 |

| 5.0 – 7.0 | 80 – 90 | 5 | 1.0 |

| >7.0 | 100 | 5 | 1.0 |

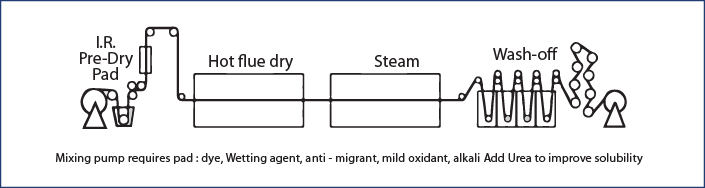

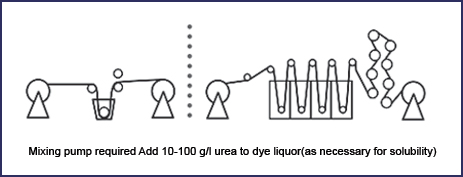

Mixing Pump REquired

| Silicate Method | ||

|---|---|---|

| Dye (g/l) | Sodium Silicate(38° Be) | Caustic Flakes (g/l) |

| <5 | 100 ml/l | 2 |

| 10 – 20 | 100 ml/l | 3 – 3.5 |

| 20 – 30 | 100 ml/l | 3.5 – 4.0 |

| 30 – 40 | 100 ml/l | 4.0 – 4.5 |

| 40 – 60 | 100 ml/l | 4.5 – 5.0 |

| 60 – 80 | 100 ml/l | 5.0 – 5.5 |

| 80 – 100 | 100 ml/l | 5.5 – 7.0 |

| Silicate Free Method | ||

|---|---|---|

| Dye(g/l) | Soda Ash(g/l) | Caustic Flakes(g/l) |

| 20 | 30 | 2 |

| 40 | 30 | 3 |

| 60 | 30 | 4 |

| 80 | 30 | 5 |

| 100 | 30 | 6 |

| >100 | 30 | 7 |

| Silicate Method | ||||||||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| % Dye | Glaubers Salt(g/l) | Soda Ash(g/l) | ||||||||||||||||||||||||||||||||||||||||

| <0.1 | 20 | 3 | ||||||||||||||||||||||||||||||||||||||||

| 0.1 – 0.5 | 20 – 25 | 3 | ||||||||||||||||||||||||||||||||||||||||

| 0.5 – 1.0 | 25 – 40 | 3 – 5 | ||||||||||||||||||||||||||||||||||||||||

| 1.0 – 2.0 | 40 – 50 | 5 – 8 | ||||||||||||||||||||||||||||||||||||||||

| 2.0 – 3.0 | 50 – 60 | 8 – 10 | ||||||||||||||||||||||||||||||||||||||||

| 3.0 – 5.0 | 60 – 80 | 10 – 12 | ||||||||||||||||||||||||||||||||||||||||

| 5.0 – 7.0 | 80 – 90 | 15 | ||||||||||||||||||||||||||||||||||||||||

| >7.0 | 100 | 20 | ||||||||||||||||||||||||||||||||||||||||

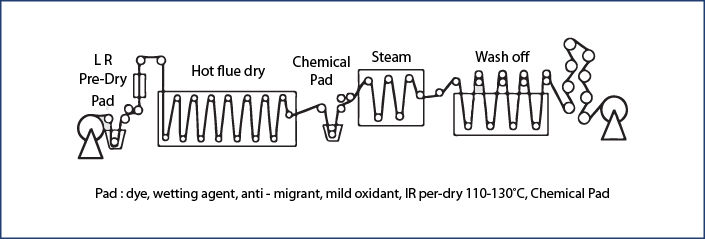

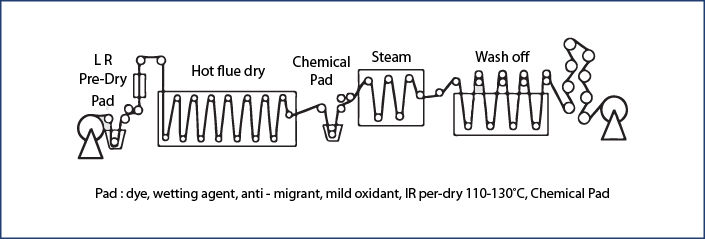

| Pad-Dry -Chemical Pad-Steam Method | |||

|---|---|---|---|

| Dye (g/l) | Common Salt (g/l) | Soda ash (g/l) | Caustic Flakes (g/l) |

| <20 | 250 | 20 | 1.5 |

| 20 – 40 | 250 | 20 | 2 |

| >40 | 250 | 20 | 3 |

| Light shades | Yellow GR |

| Orange 3R | |

| Red BB | |

| Blue BB | |

| Medium Shades | |

| Golden Yellow RNL | |

| Red RB | |

| Blue BB | |

| Deep Shades | Golden Yellow RNL |

| Red BB | |

| Navy Blue GG | |

| Black B |

- Economical multi use product range

- Broad selection available from wide shade range

- Range of products suitable for Discharge ground

- Good fastness properties

Bl – Bluer

Br – Brighter

DI – Duller

Dk – Darker

G – Greener

R – Redder

Y – Yellower

S – Suitable

NS – Not Suitable

D – Dischargeable

F – Fair (Partial Dischargeable)

P – Poor (Non Dischargeable)

Lioncion ‘P’ Printing Series

These are known as ‘HOT BRAND DYES’also These dyes are applied under strong alkaline conditions at high temperature of application specially for Printing Dyes.

| Lioncion "P" | C.I. Number | g/l |

|||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Printing | Pad Dry System | Pad Dry Thermofix | Water 30°C | AATCC 16E 1/1 | AATCC 16E 1/3 | ISO BO2 1/1 | ISO BO2 1/3 | Change in colour (Damage in Oxidative Bleach) |

Chlorinated Water 20mg/lit | ||||||||||||||

| Change in Colour | Satin(cotton) | Change in Colour | Satin(cotton) | Change in Colour | Satin(cotton) | Change in Colour | Satin(cotton) | Dry Rubbing | Wet Rubbing | ||||||||||||||

| Yellow P6GS | Y 95 | S | S | S | 60 | 5 | 4-5 | 6 | 5 | 4-5 / R | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4 | 4-5 / R | 4/R | ||

| Yellow P4G | Y 18 | S | S | NS | 200 | 5 | 4-5 | 6 | 5-6 | 5 | 4-5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 4 | 4-5 | 2-3 | ||

| G. YELLOW PR | O 12 | S | S | S | 120 | 4-5 | 4 | 6 | 5-6 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 4-5 | 4 | 4-5 | 4 | ||

| Orange P2R | O 13 | S | S | S | 200 | 3-4 | 3 | 4 | 3-4 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4-5 | 4/R | ||

| Red PB | R 24 | S | S | S | 120 | 4 | 3-4 | 5-6 | 5 | 4-5 | 4-5 | 5 | 4-5 | 4-5 | 4-5 | 5 | 4-5 | 4-5 | 3-4 | 4-5 | 3-4 | ||

| Red P2B | R 45 | S | S | NS | 40 | 4-5 | 4 | 5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4-5 | 4 | ||

| Red P6B | R 218 | S | NS | NS | 200 | 4 | 3-4 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 4-5 | 4 | 4-5 | 4 | ||

| Red P4B | R 245 | S | NS | NS | 200 | 4 | 3-4 | 4 | 3-4 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 5 | 4 | 4 / DI | 3 / DI | ||

| Magenta PB | V 26 | S | S | S | 50 | 4-5 | 4 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 4-5 | 4-5 | 4-5/BI | 4-5 | 4-5 | 4 | 4-5 | 3/DI | ||

| T. Blue P5G | B 25 | S | NS | NS | 50 | 5 | 4-5 | 6-7 | 6 | 4-5 | 3-4 | 4-5 | 3-4 | 4-5 | 4 | 4-5 | 4 | 4-5 | 3 | 4-5/Y | 2-3/Y | ||

| Blue P3R | B 49 | S | S | S | 200 | 5 | 4-5 | 6-7 | 6 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5/DI | 4-5 | 4-5/DI | 4-5 | 5 | 4 | 4 | 2-3/DI | ||

| Blue P5R | B 13 | S | S | S | 40 | 4-5 | 4 | 6 | 5-6 | 5 | 4-5 | 5 | 5 | 4-5/G | 5 | 4-5/G | 5 | 5 | 4 | 4-5 | 2 | ||

| Brown P6R | BR 11 | S | S | S | 150 | 5 | 4-5 | 6-7 | 6 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4 | 4-5 | 4 | ||

| Navy P2R | BL 39 | S | S | S | 200 | 4 | 3-4 | 4 | 3-4 | 4-5 | 4-5 | 4-5 | 5 | 4-5/G | 5 | 4-5/G | 5 | 5 | 4 | 4-5 | 3/G | ||

| Black PN | BL 8 | S | S | NS | 50 | 4 | 3-4 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4 | 5 | 3/R,DI | ||

| Black PGR | BL MIX | S | S | S | 200 | 4 | - | 5 | - | 5 | 4-5 | 5 | 4-5 | 4-5 | 4-5 | 4-5/G | 4-5 | 4-5 | 3-4 | 4-5 | 3/G | ||

| Dye | X parts |

| Urea | 50-100 |

| Water | Y parts |

| Sodium Alginate (6%) | 500 |

| Stock | 1000 |

| Substrate | Cotton | Viscose |

|---|---|---|

| Dye | X parts | X parts |

| Urea | 50 – 100 | 100 – 200 |

| Water | Y parts | Y parts |

| Sodium Alginate Paste (6%) | 500 | 500 |

| Resist Salt | 10 | 10 |

| Sodium Bicarbonate | 10 – 30 | 10 – 30 |

| Sodium Carbonate | 8 – 20 | 8 – 20 |

| Stock | 1000 | 1000 |

| Dye (g / kg) | 1 – 10 | 11-30 | 31-40 | >40 | |

|---|---|---|---|---|---|

| Sodium Bicarbonate (g/kg) | 10 | 15 | 25 | 30 | |

| Urea (g/kg) | CO | 50 | 70 | 80 | 100 |

| CV | 100 | 140 | 170 | 200 | |

| Dye (g/l) | Soda Ash (g/l) |

|---|---|

| <20 | 10 |

| >20 | 20 |

| Dye (g/l) | Soda ash (g/l) | Urea (g/l) |

|---|---|---|

| <20 | 10 | 100 |

| 20 – 50 | 15 | 150 |

| >50 | 20 | 200 |

| Lights – Medium Shades | Golden Yellow PR |

| Red 6BX | |

| Black PN | |

| Deep Shades | Golden Yellow PR |

| Red P8B | |

| Navy Blue P2R | |

| Support Shades | Yellow P6GS |

| Yellow P4G | |

| Orange P2R | |

| Red PB | |

| Magenta PB | |

| Purple P3R | |

| Turquoise Blue P5G | |

| Blue P3R | |

| Red Brown P6R | |

| Black PGR |

- Monochlorotriazine dyes having low substantivity

- High performance dyes suitable for different process

- Wide range of shades for broad shade gamut

- Good build up & reproducibility

- Good wash fastness levels

- Resistant to oxidative bleach damage

Bl – Bluer

Br – Brighter

DI – Duller

Dk – Darker

G- Greener

R – Redder

Y – Yellower

S – Suitable

Ns – Not suitable

Co – Cotton

CV – Viscose

Lioncion ‘HE’ Highly Exhausted

These are bifunctional Reactive Dyes. Which are having two reactive molties of the same type viz Monochloro Triazinyl.

| Lioncion "HE" | C.I. Number | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Affinity | Solubility at 30°C | Dischargability | Day Light 1/1 | Washing ISO4 | Hypochlorite Bleach | Exhaust 40 C & 60°C | ||||||||

| 1% | 4% | |||||||||||||

| Yellow HE-6G | Y 135 | H | 70 | G | 4 | 5 | 4 | 4-5 | 3 | 3 | S | FS | ||

| Yellow HE-4G | Y 105 | H | 80 | F | 5 | 5 | 4 | 4 | 3 | 4-5 | S | FS | ||

| G. Yellow HE-4R | Y 84 | H | 80 | F | 5 | 5 | 4 | 4 | 3 | 4-5 | S | FS | ||

| ORANGE-HE-2R | O 86 | H | 80 | P | 3-4 | 5 | 4 | 3 | 3 | 4 | S | NS | ||

| ORANGE HE-R | O 84 | H | 80 | P | 4 | 5 | 4-5 | 4 | 3 | 4 | S | NS | ||

| RED HE-3B | R 120 | H | 80 | P | 4 | 5 | 4-5 | 4 | 3 | 4 | S | NS | ||

| RED HE-7B | R 141 | H | 80 | P | 3-4 | 4 | 4-5 | 4 | 3 | 4-5 | S | FS | ||

| RED HE-8B | R 152 | H | 80 | P | 3-4 | 4 | 4 | 4-5 | 2 | 4-5 | FS | NS | ||

| N.BLUE HE-R | B 171 | H | 80 | F | 4 | 4-5 | 5 | 4-5 | 3 | 4-5 | S | FS | ||

| N.BLUE HE-2R | B 172 | H | 80 | F | 4 | 4-5 | 5 | 4-5 | 3 | 4-5 | S | FS | ||

| BLUE HE-RD | B 160 | H | 80 | F | 5 | 5 | 5 | 5 | 1 | 4-5 | S | FS | ||

| BLUE HE-GN | B 198 | H | 80 | P | 4-5 | 5 | 4 | 4 | 3 | 4 | 5 | FS | ||

| GREEN HE-4BD | G 19 | H | 80 | F | 4 | 3 | 4 | 4 | 2 | 3 | S | FS | ||

| Cotton | ||

|---|---|---|

| % Dye | Common Salt(g/l) | Soda Ash(g/l) |

| <0.2 | 30 | 10 |

| 0.2 – 0.5 | 30 – 45 | 10 |

| 0.5 – 1.0 | 45 – 60 | 15 |

| 1.0 – 2.0 | 60 – 80 | 15 |

| 2.0 – 3.0 | 80 – 85 | 20 |

| 3.0 – 4.0 | 85 – 90 | 20 |

| > – 4.0 | 90 | 20 |

| Viscose/Mercerised Cotton | ||

|---|---|---|

| % Dye | Common Salt(g/l) | Soda Ash(g/l) |

| <0.2 | 20 | 10 |

| 0.2 – 0.5 | 20 – 30 | 10 |

| 0.5 – 1.0 | 30 – 35 | 15 |

| 1.0 – 2.0 | 35 – 45 | 15 |

| 2.0 – 3.0 | 45 – 55 | 15 |

| 3.0 – 4.0 | 55 – 65 | 20 |

| >4.0 | 70 | 20 |

| Light shades | Yellow HE-4R |

| Red HE-3B | |

| Blue HE-RD | |

| Medium Deep Shades | Yellow HE-4R |

| Red HE-7B | |

| Navy Blue HE-R | |

| Support dyes | Yellow HE-6G |

| Yellow HE4G | |

| Orange HE-R | |

| Blue HE-GN |

- Economical bis MCT dyes

- Wide range of products to cover broad shade gamut

- Good wash fastness level & good reproducibility

- Good buildup behaviors for deep shades

- Level dyeing of difficult substrate with He-XL dyes

Bl – Bluer

Br – Brighter

DI – Duller

Dk – Darker

G – Greener

R – Redder

Y – Yellower

S – Suitable

NS – Not Suitable

LIONFIX ‘ME’ Bi Functional Series

The optimum fixation temperature of HE type dyes is 80-85 C. We in LION COLOR introduced a new range of Bifunctional Reactive

| Lionfix "ME" | C.I. Number | ||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Substantivity | Solubility at 30°C | Dischargeability | Day Light 1/1 | Washing ISO4 | Hypochlorite Bleach | Peroxide Bleach | Exhaust 40 C & 60°C | One Bath Pad Batch | One Bath Pad Dry Steam | ||||||||

| 1% | 4% | ||||||||||||||||

| Yellow ME-4GL | Y 160 | M | 100 | F | 6 | 4 | 4-5 | 4-5 | 1 | 4 | S | FS | NS | S | S | ||

| G. Yellow ME-RL | Y 145 | M | 100 | P | 5 | 3-4 | 4 | 4 | 1 | 3-4 | S | FS | S | S | S | ||

| Orange ME-2RL | O 122 | H | 75 | P | 5 | 4-5 | 4-5 | 4-5 | 3 | 4 | S | S | S | S | S | ||

| Scarlet - 2G | R 222 | H | 70 | P | 5 | 4-5 | 4-5 | 5 | 3 | 3-4 | S | S | S | S | S | ||

| RED ME-GF | R 223 | M | 100 | F | 4-5 | 4-5 | 4 | 4-5 | 2 | 2-3 | S | S | FS | FS | FS | ||

| RED ME-3BL | R 194 | H | 100 | P | 5 | 4-5 | 4-5 | 5 | 2-3 | 3 | S | S | FS | FS | FS | ||

| RED ME-4BL | R 195 | H | 150 | P | 5 | 4-5 | 5 | 5 | 1 | 4 | S | S | S | S | S | ||

| RED ME-6BL | R 250 | H | 80 | P | 5 | 4-5 | 5 | 5 | 1 | 4 | S | S | S | S | S | ||

| VIOLET MEB2 | - | H | 80 | P | 3 | 4 | 4 | 3 | 2 | 3 | S | FS | S | S | S | ||

| SKY BLUE FGN | B 187 | M | 100 | F | 4 | 4 | 4 | 4 | 4 | 4 | S | FS | S | S | S | ||

| BLUE BRF | B 221 | H | 100 | P | 5 | 5 | 4 | 4-5 | 2 | 3-4 | S | S | FS | FS | S | ||

| BLUE ME-2RL | B 248 | H | 100 | P | 4 | 5 | 5 | 5 | 1 | 3 | S | S | S | S | S | ||

| N. BLUE ME-2GL | B 194 | H | 100 | F | 6 | 5 | 5 | 5 | 1 | 3 | S | NS | S | FS | FS | ||

| N. BLUE MEBF | B 222 | H | 100 | G | 3-4 | 4-5 | 5 | 5 | 1 | 3 | S | NS | S | FS | FS | ||

| Single Alkali Method | ||

|---|---|---|

| % Dye | Common Salt(g/l) | Soda Ash(g/l) |

| <0.1 | 20 | 5 |

| 0.1 – 0.5 | 20 – 25 | 5 – 7 |

| 0.5 – 1.0 | 25 – 40 | 7 – 10 |

| 1.0 – 2.0 | 40 – 50 | 10 – 13 |

| 2.0 – 3.0 | 50 – 60 | 13 – 15 |

| 3.0 – 5.0 | 60 – 80 | 15 – 20 |

| 5.0 – 7.0 | 80 – 90 | 20 |

| >7.0 | 100 | 20 |

| Mixed Alkali Method | |||

|---|---|---|---|

| % Dye | Common Salt(g/l) | Soda Ash(g/l) | Caustic Flakes(g/l) |

| <0.1 | 20 | 5 | 0 |

| 0.1 – 0.5 | 20 – 25 | 5 | 0.3 – 0.38 |

| 0.5 – 1.0 | 25 – 40 | 5 | 0.38 – 0.45 |

| 1.0 – 2.0 | 40 – 50 | 5 | 0.45 – 0.6 |

| 2.0 – 3.0 | 50 – 60 | 5 | 0.6 – 0.75 |

| 3.0 – 5.0 | 60 – 80 | 5 | 0.75 – 1.0 |

| 5.0 – 7.0 | 80 – 90 | 5 | 1.0 |

| >7.0 | 100 | 5 | 1.0 |

| Light shades | Golden Yellow MERL |

| Red ME4BL | |

| Blue BRF | |

| Medium Shades | Golden Yellow MERL |

| Red ME4BL | |

| Blue ME2GL | |

| Deep SHades | Golden Yellow MERL |

| Red ME4BL | |

| Navy MEBF | |

| Support dyes | Yellow ME4GL |

| Orange ME2RL | |

| SCARLET 2G | |

| Red MEGF | |

| Red ME3BL | |

| Red ME6BL |

- Commodity Bl-Functional dyes for economical shades

- Wide range of products to cover broad shade gamut

- Good build-up behaviour for deep shades

- Good wash fastness levels & good reproducibility

Bl – Bluer

Br – Brighter

DI – Duller

Dk – Darker

G – Greener

R – Redder

Y = Yellower

S – Suitable

NS – Not Suitable

LIONZOL RGB

| Lionzol "RGB" | Light | Washing ISO 4 | Acidic Perspiration | Alkaline Perspiration | Hypochlorite Bleach | Peroxide Bleach | Dischargeability | Solubility 60°C | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 1% | 4% | |||||||||

| Yellow RGB | 4-5 | 4-5 | 5 | 4-5 | 2 | 2 | F | 100 | ||

| Orange RGB | 4-5 | 4-5 | 4 | 4 | 4-5 | 4-5 | F | 100 | ||

| Red RGB | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4 | P | 120 | ||

| Deep Red RGB | 4-5 | 4 | 4 | 4-5 | 4 | 4-5 | P | 120 | ||

| Carmine RGB | 4 | 4 | 4 | 4 | 3-4 | 3-4 | D | 100 | ||

| Navy RGB | 5 | 5 | 5 | 5 | 3 | 3 | D | 120 | ||

| Deep Black RGB | 4 | 4 | 4 | 4 | 3-4 | 3-4 | D | 100 | ||

| Single Alkali Method | ||

|---|---|---|

| % Dye | Common Salt(g/l) | Soda Ash(g/l) |

| <0.1 | 20 | 5 |

| 0.1 – 0.5 | 20 – 25 | 5 – 7 |

| 0.5 – 1.0 | 25 – 40 | 7 – 10 |

| 1.0 – 2.0 | 40 – 50 | 10 – 13 |

| 2.0 – 3.0 | 50 – 60 | 13 – 15 |

| 3.0 – 5.0 | 60 – 80 | 15 – 20 |

| 5.0 – 7.0 | 80 – 90 | 20 |

| >7.0 | 100 | 20 |

| Mixed Alkali Method | |||

|---|---|---|---|

| % Dye | Common Salt(g/l) | Soda Ash(g/l) | Caustic Flakes(g/l) |

| <0.1 | 20 | 5 | 0 |

| 0.1 – 0.5 | 20 – 25 | 5 | 0.3 – 0.38 |

| 0.5 – 1.0 | 25 – 40 | 5 | 0.38 – 0.45 |

| 1.0 – 2.0 | 40 – 50 | 5 | 0.45 – 0.6 |

| 2.0 – 3.0 | 50 – 60 | 5 | 0.6 – 0.75 |

| 3.0 – 5.0 | 60 – 80 | 5 | 0.75 – 1.0 |

| 5.0 – 7.0 | 80 – 90 | 5 | 1.0 |

| >7.0 | 100 | 5 | 1.0 |

| Silicate Method | ||

|---|---|---|

| Dye (g/l) | Sodium Silicate(38° Be) | Caustic Flakes (g/l) |

| <5 | 100 ml/l | 2 |

| 10 – 20 | 100 ml/l | 3 – 3.5 |

| 20 – 30 | 100 ml/l | 3.5 – 4.0 |

| 30 – 40 | 100 ml/l | 4.0 – 4.5 |

| 40 – 60 | 100 ml/l | 4.5 – 5.0 |

| 60 – 80 | 100 ml/l | 5.0 – 5.5 |

| 80 – 100 | 100 ml/l | 5.5 – 7.0 |

| Silicate Free Method | ||

|---|---|---|

| Dye(g/l) | Soda Ash(g/l) | Caustic Flakes(g/l) |

| 20 | 30 | 2 |

| 40 | 30 | 3 |

| 60 | 30 | 4 |

| 80 | 30 | 5 |

| 100 | 30 | 6 |

| >100 | 30 | 7 |

| Light – Medium shades | Golden Yellow RGB |

| Red RGB | |

| Deep Shades | Yellow RGB |

| Deep Red RGB | |

| Navy RGB | |

| Very Heavy Shades | Yellow RGB Conc. |

| Red RGB Conc. | |

| Navy RGB Conc. |

- Modified Bl-Functional dyes

- Very good leveling & Compatibility

- Suitable for light to medium depths

- Suitable for medium to deep depths

- Good build up properties

- Resistant to oxidative bleach damage

Bl – Bluer

Br – Brighter

DI – Duller

Dk – Darker

G – Greener

R – Redder

Y – Yellower

S – Suitable

NS – Not Suitable

D – Dischargeability

F – Fair (Partial dischargeable)

P – Poor (Non dischargeable)

LIONZOL BLACK

| Lionzol "Black" | Light | Washing ISO 4 | Acidic Perspiration | Alkaline Perspiration | Hypochlorite Bleach | Peroxide Bleach | Dischargeability | Solubility 60°C | ||

|---|---|---|---|---|---|---|---|---|---|---|

| 4% | 8% | |||||||||

| Black WNN | 4-5 | 5 | 5 | 5 | 3-4 | 3-4 | D | 150 | ||

| Black DN | 4-5 | 5 | 5 | 5 | 3-4 | 3-4 | D | 150 | ||

| Black NG | 4-5 | 5 | 5 | 5 | 3-4 | 3-4 | D | 150 | ||

| Black PFR | 4 | 4 | 4-5 | 4-5 | 3-4 | 3-4 | D | 120 | ||

| Deep Black ED | 4 | 5 | 5 | 5 | 3-4 | 3-4 | D | 150 | ||

| Deep Black EDR | 4 | 5 | 5 | 5 | 3-4 | 3-4 | D | 150 | ||

| Deep Black GWF | 3-4 | 5 | 5 | 5 | 3-4 | 3-4 | D | 150 | ||

| Black GSP | 3-4 | 4 | 4 | 4 | 3-4 | 3-4 | D | 140 | ||

| Black N150 | 3-4 | 5 | 5 | 5 | 3-4 | 3-4 | D | 150 | ||

| Black HFGR | 4-5 | 5 | 5 | 5 | 3-4 | 3-4 | D | 150 | ||

| Black Mix-N | 4-5 | 5 | 5 | 5 | 3-4 | 3-4 | D | 150 | ||

| Black DSDN | 4-5 | 5 | 5 | 5 | 3-4 | 3-4 | D | 150 | ||

| Black NN | 4 | 4 | 4-5 | 4-5 | 3-4 | 3-4 | D | 120 | ||

| Black EDR | 4 | 5 | 5 | 5 | 3-4 | 3-4 | D | 150 | ||

| Black SD | 3-4 | 4 | 4 | 4 | 3-4 | 3-4 | D | 140 | ||

| Jet Black RD | 3-4 | 5 | 5 | 5 | 3-4 | 3-4 | D | 150 | ||

| Direct Black 22 | 2-3 | 3-4 | 4 | 4 | 4 | 4 | D | 30 | ||

| Acid Black 194 | 6 | 4-5 | 4 | 4 | 4 | 3-4 | D | 65 | ||

LIONCRON S - DYES

"S-Dyes" |

ISO 105 B02 72/168h |

AATCC 16E 1/1 SD |

ISO 105 C06 C1S |

ISO 105 E04 Ch/CO |

ISO 105 E03 20MG/I |

AATCO 164 3cyc es |

|||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Lemon S-3G | 3/4 | 4/5 | 4/5 | 4/5 | 5/5 | 5/5 | 3/4 | 4 | 5 | ||

| Yellow S-3R | 3/4 | 5 | 4/5 | 4/5 | 5/5 | 4/5 | 2/3 | 5 | 5 | ||

| Deep Orange S-4R | 3/4 | 3 | 3 | 4/5 | 5/5 | 5/5 | 4 | 4/5 | 5 | ||

| Red S-2G | 3/4 | 4/5 | 4 | 5/5 | 4/5 | 4/5 | 2/3 | 4/5 | 3 | ||

| Deep Cherry S-D | 4/5 | 4/5 | 4 | 4/5 | 4/5 | 5/5 | 4/5 | 4/5 | 4/5 | ||

| Red S-B | 3/4 | 4/5 | 4 | 4/5 | 5/4 | 4/5 | 2/3 | 2 | 5 | ||

| Ruby S-3B | 3/4 | 4/5 | 4 | 4/5 | 4/5 | 4/5 | 4/5 | 5 | 4/5 | ||

| Ocean S-R | 5 | 4/5 | 4/5 | 4/5 | 4/5 | 4/5 | 1/2 | 4/5 | 3/4 | ||

| Dark Blue S-GL | 3/4 | 5 | 4 | 5/5 | 5/5 | 5/5 | 3/4 | 4/5 | 3/4 | ||

| Navy S-G | 4/5 | 5 | 4/5 | 5/5 | 5/5 | 5/5 | 4/5 | 5 | 4 | ||

| Deep Night S-R | 4/5 | 4/5 | 4 | 4/5 | 5 | 5 | 2/3 | 3 | 4/5 | ||

| Black NN | 5 | 4/5 | 4/5 | 4/5 | 5/5 | 5/5 | 4/5 | 4 | 5 | ||

| S. Black G | 5 | 5 | 4/5 | 4/5 | 5 | 5 | 4 | 4 | 5 | ||

| S. Black R | 5 | 5 | 4 | 4/5 | 5 | 4/5 | 4/5 | 4 | 4/5 | ||

| Liquor ration below 6:1 | |||||||

|---|---|---|---|---|---|---|---|

| Dye % | <0.5 | 0.5 | 1 | 2 | 3 | 4 | >5 |

| Salt(g/l) | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

| Soda Ash(g/l) | 14 | 16 | 18 | 20 | 20 | 20 | 20 |

| Liquor ration below 8:1 | |||||||

|---|---|---|---|---|---|---|---|

| Dye % | <0.5 | 0.5 | 1 | 2 | 3 | 4 | >5 |

| Salt(g/l) | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

| Soda Ash(g/l) | 10 | 12 | 14 | 16 | 18 | 20 | 20 |

| Liquor ration at and above 8:1 | |||||||

|---|---|---|---|---|---|---|---|

| Dye % | <0.5 | 0.5 | 1 | 2 | 3 | 4 | >5 |

| Salt(g/l) | 30 | 40 | 50 | 60 | 80 | 80 | 100 |

| Soda Ash(g/l) | 8 | 10 | 12 | 14 | 16 | 18 | 18 |

| Liquor ration below 6:1 | |||||||

|---|---|---|---|---|---|---|---|

| Dye % | <0.5 | 0.5 | 1 | 2 | 3 | 4 | >5 |

| Salt(g/l) | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

| Soda Ash(g/l) | 10 | 10 | 5 | 5 | 5 | 5 | 5 |

| NaOH 36°Bej66°Tw% | 0.5 | 1 | 2 | 2.5 | 3 | 3.5 | 4 |

| Liquor ration below 8:1 | |||||||

|---|---|---|---|---|---|---|---|

| Dye % | <0.5 | 0.5 | 1 | 2 | 3 | 4 | >5 |

| Salt(g/l) | 20 | 30 | 40 | 50 | 60 | 70 | 80 |

| Soda Ash(g/l) |

10 | 10 | 5 | 5 | 5 | 5 | 5 |

| NaOH 36°Bej66°Tw% | – | 0.75 | 1.25 | 1.5 | 2 | 2.5 | 3 |

| Liquor ration at and above 8:1 | |||||||

|---|---|---|---|---|---|---|---|

| Dye % | <0.5 | 0.5 | 1 | 2 | 3 | 4 | >5 |

| Salt(g/l) | 30 | 40 | 50 | 60 | 80 | 80 | 100 |

| Soda Ash(g/l) | 8 | 5 | 5 | 5 | 5 | 5 | 5 |

| NaOH 36°Bej66°Tw% | – | 0.5 | 1 | 1.25 | 1.5 | 2 | 2.5 |

| Liquor ration at and above 8:1 | |||||||

|---|---|---|---|---|---|---|---|

| Product | Placement | Warm Exhaust | Hot Exhaust | Cold Pad Batch | Pad Dry Chemical Pad System |

Printing | |

| Lioncron | High Performance Printing | s | |||||

| Lioncron | Economical Warm exhaust dyeing | s | s | ||||

| Lioncron | Commodity multi-use vinyl sulphone | s | s | s | s | ||

| Lioncron | High Performance dyeing (Md-Dp shades) | s | s | ||||

| WASHING OFF METHOD – S DYES | |

|---|---|

| Rinse for 10 min at 50 C/122 F | One rinse in sufficient if liquor ratio is 10:1 if liquor ratio is below 10:1, overflow or intermittent rinse |

| Neutralize for 10 min at 50 C/122 F | Acetid acid (PH=5.5 to 6) |

| Soap for 10 min at 95 C /194 F | The addition of a soaping agent is advisable.See dyeing Additives/Soaping |

| Soap for 10 min at 95 C /194 F | A second soaping operation is recommended for very deep shades |

| Rinse for 10 min at 70 C/122 F | |

| Rinse for 10 min cold | |

| Soften as usual or aftertreat | See dyeing additives/after treatment |

| Single Alkali Method | ||

|---|---|---|

| % Dye | Common Salt(g/l) | Soda Ash(g/l) |

| <0.1 | 20 | 5 |

| 0.1 – 0.5 | 20 – 25 | 5 – 7 |

| 0.5 – 1.0 | 25 – 40 | 7 – 10 |

| 1.0 – 2.0 | 40 – 50 | 10 – 13 |

| 2.0 – 3.0 | 50 – 60 | 13 – 15 |

| 3.0 – 5.0 | 60 – 80 | 15 – 20 |

| 5.0 – 7.0 | 80 – 90 | 20 |

| >7.0 | 100 | 20 |

| Mixed Alkali Method | |||

|---|---|---|---|

| % Dye | Common Salt(g/l) | Soda Ash(g/l) | Caustic Flakes(g/l) |

| <0.1 | 20 | 5 | 0 |

| 0.1 – 0.5 | 20 – 25 | 5 | 0.3 – 0.38 |

| 0.5 – 1.0 | 25 – 40 | 5 | 0.38 – 0.45 |

| 1.0 – 2.0 | 40 – 50 | 5 | 0.45 – 0.6 |

| 2.0 – 3.0 | 50 – 60 | 5 | 0.6 – 0.75 |

| 3.0 – 5.0 | 60 – 80 | 5 | 0.75 – 1.0 |

| 5.0 – 7.0 | 80 – 90 | 5 | 1.0 |

| >7.0 | 100 | 5 | 1.0 |

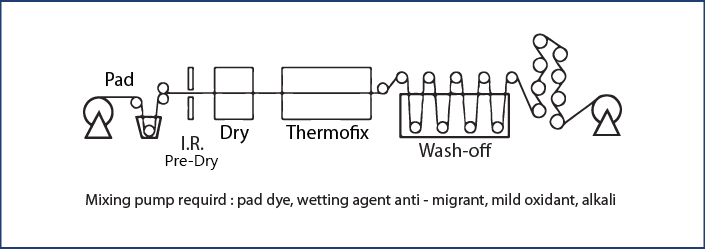

Mixing Pump REquired

| Silicate Method | ||

|---|---|---|

| Dye (g/l) | Sodium Silicate(38° Be) | Caustic Flakes (g/l) |

| <5 | 100 ml/l | 2 |

| 10 – 20 | 100 ml/l | 3 – 3.5 |

| 20 – 30 | 100 ml/l | 3.5 – 4.0 |

| 30 – 40 | 100 ml/l | 4.0 – 4.5 |

| 40 – 60 | 100 ml/l | 4.5 – 5.0 |

| 60 – 80 | 100 ml/l | 5.0 – 5.5 |

| 80 – 100 | 100 ml/l | 5.5 – 7.0 |

| Silicate Free Method | ||

|---|---|---|

| Dye(g/l) | Soda Ash(g/l) | Caustic Flakes(g/l) |

| 20 | 30 | 2 |

| 40 | 30 | 3 |

| 60 | 30 | 4 |

| 80 | 30 | 5 |

| 100 | 30 | 6 |

| >100 | 30 | 7 |

| Pad-Dry -Chemical Pad-Steam Method | |||

|---|---|---|---|

| Dye (g/l) | Common Salt (g/l) | Soda ash (g/l) | Caustic Flakes (g/l) |

| <20 | 250 | 20 | 1.5 |

| 20 – 40 | 250 | 20 | 2 |

| >40 | 250 | 20 | 3 |

| Light - Medium shades | Yellow S-3R |

| Deep Orange S-4R | |

| Dark Blue S-GL | |

| Red S-2G | |

| Deep Shades | |

| Yellow S-3R | |

| Deep Orange S-4R | |

| Red S-B | |

| Navy S-G | |

| Support Dyes | Lemon S-3G |

| Deep Cherry S-D | |

| Ruby S-3B | |

| Red S-2G | |

| Deep Night S-R | Jet Black | Greener Black - Black G |

| Redder Black - Black R | |

| Neutral Black - Black NN |

- Hetero Bl-Functional dyes for medium to deep shades

- Very good buildup behaviour

- Good wash fastness level & good repoducibility

- Resistant to oxidative bleach damage

Bl – Bluer

Br – Brighter

DI – Duller

Dk – Darker

G – Greener

R – Redder

Y – Yellower

S – Suitable

NS – Not Suitable

D – Dischargeable

F – Fair (Partial Dischargeable)

P – Poor (Non Dischargeable)

LIONZOL ULTRA & DS

| Lionzol "Ultra" & "DS" | Dyeing Depth(%) | C.I. Reactive | Solubility (g/l) | Light | Chlorinated Water | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1% | 4% | Neutral | Alkaline | Cu++ | Fe++ | Alteration | Staining | ||||||

| Yellow DS-2G | 3.0 | Unknown | 100 | 4 | 4 | 4 | 4RD | 4-5 | 4-5 | 4 | 3-4 | ||

| Ultra Yellow DS | 3.0 | Unknown | 100 | 4-5 | 4-5 | 4-5 | 4RD | 4-5 | 4-5 | 4-5 | 3 | ||

| Orange DS-2R | 3.0 | Unknown | 100 | 2-3 | 2-3 | 4 | 3BD | 4-5 | 4-5 | 4 | 4 | ||

| Ultra Orange DS | 3.0 | Unknown | 100 | 4 | 4 | 4 | 4BD | 4-5 | 4-5 | 4 | 3-4 | ||

| Orange DS-HR | 3.0 | Unknown | 100 | 4 | 4 | 4 | 4BD | 4-5 | 4-5 | 4 | 3-4 | ||

| Ultra Red DS | 3.0 | Unknown | 100 | 2-3 | 2-3 | 4 | 4Y | 4-5 | 4-5 | 4-5 | 4 | ||

| Ultra Wine DS | 3.0 | Unknown | 100 | 2-3 | 2-3 | 4 | 4BD | 4-5 | 4-5 | 4-5 | 3-4 | ||

| Red DS-3B | 3.0 | Unknown | 200 | 2-3 | 2-3 | 4 | 4BD | 4-5 | 4-5 | 4-5 | 3-4 | ||

| Red DS-4B | 3.0 | Unknown | 100 | 2-3 | 2-3 | 4 | 4BD | 4-5 | 4-5 | 4-5 | 4 | ||

| Red DS-2R | 3.0 | Unknown | 100 | 2-3 | 2-3 | 4 | 4BD | 4-5 | 4-5 | 4-5 | 4 | ||

| Red DS-HR | 3.0 | Unknown | 150 | 2-3 | 2-3 | 4 | 4BD | 4-5 | 4-5 | 4-5 | 4 | ||

| Blue DS-RS | 3.0 | Unknown | 100 | 2 | 2 | 5-6 | 4-5Y | 5 | 4-5 | 4-5 | 4-5 | ||

| Ultra Blue DS | 3.0 | Unknown | 100 | 2-3 | 2-3 | 4 | 3YG | 4-5 | 4-5 | 4 | 4 | ||

| Navy Blue DS-2G | 3.0 | Unknown | 100 | 4-5 | 4-5 | 4 | 2G | 4-5 | 4-5 | 4-5 | 4 | ||

| Ultra Navy SDR | 3.0 | Unknown | 150 | 4-5 | 4-5 | 4 | 2R | 4-5 | 4-5 | 4-5 | 3-4 | ||

- Applicable for cost effective medium to dark shades.

- It can be applied in continuos dyeing, printing and exhaust dying.

- High reproducibility and good overall fastness.

- Increased build up properties.

LIONZOL DLF

| Lionzol "DLF" | Dyeing Depth(%) | C.I.Reactive | Solubility (g/l) | Light | Chlorinated Water | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1% | 4% | Neutral | Alkaline | Cu++ | Fe++ | Alteration | Staining | ||||||

| Yellow DLF | 1.0 | Unknown | 200 | 4 | 4 | 4-5 | 3-4YD | 3-4YD | 5 | 4 | 4 | ||

| Red DLF | 1.0 | Unkonwn | 100 | 3 | 3 | 4-5 | 1-2B | 1-2B | 5 | 5 | 2-3 | ||

| Blue DLF | 1.0 | Unknown | 150 | 2 | 2 | 5 | 5 | 4 | 4-5 | 4 | 4 | ||

- Economic light fastness dyestuffs.

- Good reproducibility and compatibility.

- Suitable for trichromatic dyeing in light fastness.

- Suitable for exhaust dyeing and continuous dyeing process.

LIONFIX SPD CONC

| Lionfix "SPD CONC" | Dyeing Depth(%) | C.I. Reactive | Solubility (g/l) | Light | Chlorinated Water | ||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1% | 4% | Neutral | Alkaline | Cu++ | Fe++ | Alteration | Staining | ||||||

| Yellow SPD Conc | 3.0 | Unknown | 200 | 4 | 4 | 5 | 4-5 | 4-5 | 5 | 4-5 | 4-5 | ||

| Red SPD Conc | 3.0 | Unknown | 200 | 2 | 2 | 4-5 | 4BD | 4-5 | 4-5 | 4-5 | 4 | ||

| Blue SPD Conc | 3.0 | Unknown | 150 | 2 | 2 | 5 | 5 | 4 | 4-5 | 4 | 4 | ||

| Navy Blue SPD Conc | 3.0 | Unknown | 200 | 4-5 | 4-5 | 4 | 2G | 4-5 | 4-5 | 4-5 | 3-4 | ||