Lioncion "P Printing" Series

You are here: Home \ Products \ Lioncion "P Printing" Series

Lioncion ‘P’ Printing Series

These are known as ‘HOT BRAND DYES’also These dyes are applied under strong alkaline conditions at high temperature of application specially for Printing Dyes.

| Lioncion "P" | C.I. Number | g/l |

|||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Printing | Pad Dry System | Pad Dry Thermofix | Water 30°C | AATCC 16E 1/1 | AATCC 16E 1/3 | ISO BO2 1/1 | ISO BO2 1/3 | Change in colour (Damage in Oxidative Bleach) |

Chlorinated Water 20mg/lit | ||||||||||||||

| Change in Colour | Satin(cotton) | Change in Colour | Satin(cotton) | Change in Colour | Satin(cotton) | Change in Colour | Satin(cotton) | Dry Rubbing | Wet Rubbing | ||||||||||||||

| Yellow P6GS | Y 95 | S | S | S | 60 | 5 | 4-5 | 6 | 5 | 4-5 / R | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4 | 4-5 / R | 4/R | ||

| Yellow P4G | Y 18 | S | S | NS | 200 | 5 | 4-5 | 6 | 5-6 | 5 | 4-5 | 5 | 5 | 5 | 5 | 5 | 5 | 5 | 4 | 4-5 | 2-3 | ||

| G. YELLOW PR | O 12 | S | S | S | 120 | 4-5 | 4 | 6 | 5-6 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 4-5 | 4 | 4-5 | 4 | ||

| Orange P2R | O 13 | S | S | S | 200 | 3-4 | 3 | 4 | 3-4 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4-5 | 4/R | ||

| Red PB | R 24 | S | S | S | 120 | 4 | 3-4 | 5-6 | 5 | 4-5 | 4-5 | 5 | 4-5 | 4-5 | 4-5 | 5 | 4-5 | 4-5 | 3-4 | 4-5 | 3-4 | ||

| Red P2B | R 45 | S | S | NS | 40 | 4-5 | 4 | 5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4 | 4-5 | 4 | ||

| Red P6B | R 218 | S | NS | NS | 200 | 4 | 3-4 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 4-5 | 4 | 4-5 | 4 | ||

| Red P4B | R 245 | S | NS | NS | 200 | 4 | 3-4 | 4 | 3-4 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5 | 5 | 4 | 4 / DI | 3 / DI | ||

| Magenta PB | V 26 | S | S | S | 50 | 4-5 | 4 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 4-5 | 4-5 | 4-5/BI | 4-5 | 4-5 | 4 | 4-5 | 3/DI | ||

| T. Blue P5G | B 25 | S | NS | NS | 50 | 5 | 4-5 | 6-7 | 6 | 4-5 | 3-4 | 4-5 | 3-4 | 4-5 | 4 | 4-5 | 4 | 4-5 | 3 | 4-5/Y | 2-3/Y | ||

| Blue P3R | B 49 | S | S | S | 200 | 5 | 4-5 | 6-7 | 6 | 4-5 | 4-5 | 4-5 | 4-5 | 4-5/DI | 4-5 | 4-5/DI | 4-5 | 5 | 4 | 4 | 2-3/DI | ||

| Blue P5R | B 13 | S | S | S | 40 | 4-5 | 4 | 6 | 5-6 | 5 | 4-5 | 5 | 5 | 4-5/G | 5 | 4-5/G | 5 | 5 | 4 | 4-5 | 2 | ||

| Brown P6R | BR 11 | S | S | S | 150 | 5 | 4-5 | 6-7 | 6 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4 | 4-5 | 4 | ||

| Navy P2R | BL 39 | S | S | S | 200 | 4 | 3-4 | 4 | 3-4 | 4-5 | 4-5 | 4-5 | 5 | 4-5/G | 5 | 4-5/G | 5 | 5 | 4 | 4-5 | 3/G | ||

| Black PN | BL 8 | S | S | NS | 50 | 4 | 3-4 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4-5 | 5 | 4 | 5 | 3/R,DI | ||

| Black PGR | BL MIX | S | S | S | 200 | 4 | - | 5 | - | 5 | 4-5 | 5 | 4-5 | 4-5 | 4-5 | 4-5/G | 4-5 | 4-5 | 3-4 | 4-5 | 3/G | ||

Print Silicate

Print - Dry- Stream / Print - Dry - Bake

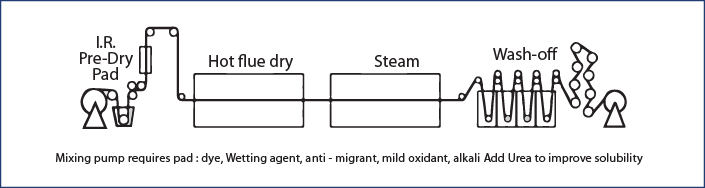

Pad - Dry- Stream (Cotton & viscose)

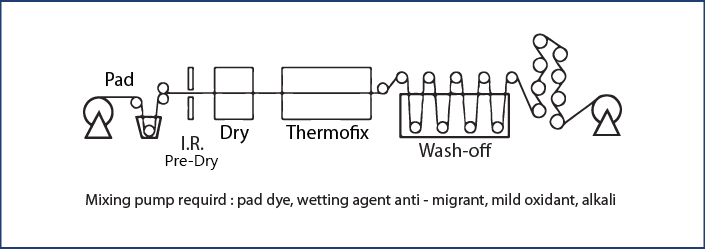

Pad-Dry -Thermofix (cotton)

| Dye | X parts |

| Urea | 50-100 |

| Water | Y parts |

| Sodium Alginate (6%) | 500 |

| Stock | 1000 |

| Substrate | Cotton | Viscose |

|---|---|---|

| Dye | X parts | X parts |

| Urea | 50 – 100 | 100 – 200 |

| Water | Y parts | Y parts |

| Sodium Alginate Paste (6%) | 500 | 500 |

| Resist Salt | 10 | 10 |

| Sodium Bicarbonate | 10 – 30 | 10 – 30 |

| Sodium Carbonate | 8 – 20 | 8 – 20 |

| Stock | 1000 | 1000 |

| Dye (g / kg) | 1 – 10 | 11-30 | 31-40 | >40 | |

|---|---|---|---|---|---|

| Sodium Bicarbonate (g/kg) | 10 | 15 | 25 | 30 | |

| Urea (g/kg) | CO | 50 | 70 | 80 | 100 |

| CV | 100 | 140 | 170 | 200 | |

| Dye (g/l) | Soda Ash (g/l) |

|---|---|

| <20 | 10 |

| >20 | 20 |

| Dye (g/l) | Soda ash (g/l) | Urea (g/l) |

|---|---|---|

| <20 | 10 | 100 |

| 20 – 50 | 15 | 150 |

| >50 | 20 | 200 |

Product Placement

Advantage

Abbreviations

| Lights – Medium Shades | Golden Yellow PR |

| Red 6BX | |

| Black PN | |

| Deep Shades | Golden Yellow PR |

| Red P8B | |

| Navy Blue P2R | |

| Support Shades | Yellow P6GS |

| Yellow P4G | |

| Orange P2R | |

| Red PB | |

| Magenta PB | |

| Purple P3R | |

| Turquoise Blue P5G | |

| Blue P3R | |

| Red Brown P6R | |

| Black PGR |

- Monochlorotriazine dyes having low substantivity

- High performance dyes suitable for different process

- Wide range of shades for broad shade gamut

- Good build up & reproducibility

- Good wash fastness levels

- Resistant to oxidative bleach damage

Bl – Bluer

Br – Brighter

DI – Duller

Dk – Darker

G- Greener

R – Redder

Y – Yellower

S – Suitable

Ns – Not suitable

Co – Cotton

CV – Viscose